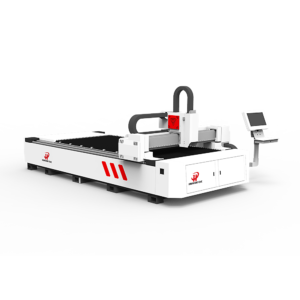

Tube Laser Cutting Machine

This metal tube laser cutting machine is specially designed for cutting metal tubes and pipes. Except for regular round pipes and square tubes, it can also cut H-shaped, L-shaped, T-shaped, and U-shaped steel materials. The pneumatic rotating chucks can fix and rotate the pipes and tubes to make the cutting faster and more convenient.

Additional information

| Brand | HISMART CNC |

|---|---|

| Model | HS6230T |

| Category | Laser Tube Cutting Machine |

| Price range | $21000 to $50000/set based on configuration |

| Payment | TT, Visa, Mastercard, Credit Cards, Paypal |

| Supply Ability | 200Sets/month |

Product Details:

It can be configured with 500mm chucks to meet the processing needs of large-diameter and heavy-duty pipe industries.

Description

This metal tube laser cutting machine is specially designed for cutting metal tubes and pipes. Except for regular round pipes and square tubes, it can also cut H-shaped, L-shaped, T-shaped, and U-shaped steel materials. The pneumatic rotating chucks can fix and rotate the pipes and tubes to make the cutting faster and more convenient.

Features

1. Heavy-duty high-strength mechanical structure It adopts high-strength machine bed which has gone through stress relief annealing treatment under 600℃. The strong rigidity of the machine structure maintains small deformation, low vibration, and high precision of the laser cutting machine.

2. TubePro pipe cutting software It uses a professional pipe cutting system, which supports high-speed and high-efficiency cutting of various pipes and tubes. It has automatic pipe centering and eccentric compensation functions, ensuring the cutting accuracy. The software helps increase the utilization rate of materials, reduces residual material, and saves production costs.

3. Automatic focusing laser head Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

4. Automatic support device. Adopting the intelligent pipe holder design, this machine solves the deformation problem in the process of long pipe cutting.

5. Automatic double pneumatic chucks, stable and efficient The chuck device is controlled by one key and can realize automatic centering, reducing the waiting time for loading and unloading. The constant and large clamping force guarantees no loose or sliding of heavy pipes, thus ensuring the cutting precision. It is also equipped with special support frame to avoid pipe sagging deformation, and to improve the cutting accuracy while extending the life of the chuck.

6. Enclosed processing area The cutting area is protected by a fully enclosed cover, protecting operator’s safety and working environment.

Parameters

| Model | HS6160T/HS9160T | HS6230T/HS9230T | HS6350T/HS9350T |

| Max. tube length | 6.5/9.2m | 6.5/9.2m | 6.5/9.2m |

| Tube shape | Round/square/rectangular | Round/square/rectangular | Round/square/rectangular |

| Max. tube weight | 100Kg 16kg/m | 300kg 35kg/m | 500kg 83kg/m |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Chuck | Two pneumatic chucks | Two pneumatic chucks | Two pneumatic chucks |

| Max. chuck rotating speed | 130r/min | 130r/min | 140r/min |

| Laser power | 1KW-4KW | 1KW-4KW | 1KW-4KW |

| Laser | Multiple options | Multiple options | Multiple options |

| Clamping range | φ10-φ160mm | φ20-φ230mm | φ20-φ350mm |

Application

Fiber laser cutting machines provide large and small companies with economical and affordable laser cutting capabilities for metals. For example, stainless steel, carbon steel, galvanized, aluminum, etc. Therefore, the company has a good opportunity to laser cut highly complex metal parts, prototypes and custom parts in a cost-effective manner internally. This metal tube fiber laser cutting machine is widely used to cut various pipes and tubes.