If you are considering buying a laser cutting machine, there are a few things that you should look for. These factors include the price range, the quality of the optics, and the bed size. By following these tips, you will be able to make a more informed purchase.

Considerations before buying a laser cutting machine

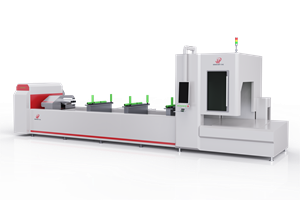

Laser cutting machines are an excellent tool to add to your business, but there are several things to consider before buying one. Investing in a good machine is not only a smart idea, but it can also be very profitable. The machine you buy must be durable and should last for many years. It should be easy to repair if it breaks down or has any other problems. You should also check if the company offering the laser cutting machine has a good network of service technicians.

Another factor to consider is your budget. A higher budget will get you a more reliable and powerful laser. However, a cheaper machine may be easier to operate, especially if you are a beginner.

Price range

The price range of a laser cutting machine varies depending on the features and the capabilities of the machine. A high-end machine can cost as much as PS10,000 while a more affordable model can cost around PS200. Laser cutting is one of the most advanced cutting methods and offers high precision and low waste. This makes it a viable option for applications that require accurate results with limited budgets.

Laser cutting equipment has many benefits, but the price range of a machine depends on the type of laser used. CO2 lasers are the cheapest type, but they are relatively limited in operations and have high operational costs. On the other hand, fiber lasers are more accurate and have lower operational costs. Because of this, the price of a fiber laser cutting machine is higher than that of a CO2 machine.

Quality of the optics

The optics of a laser cutting machine are critical to the cutting process. The quality of the optics determines the precision and speed of the cut. Some types of materials are more difficult to cut than others, and the quality of the optics is important in these cases. Pure aluminum, for example, is a difficult material to cut. This material must be processed with a device that eliminates reflection from the cutting surface. Other materials, such as titanium plates, require processing with argon or nitrogen. Some materials such as nickel chromium steel are more difficult to cut, but they are also highly reflective and have good thermal conductivity. Other materials, such as copper and brass, can be cut with oxygen or nitrogen.

Laser cutting machines with high laser power should be purchased for jobs requiring medium or thick sheets. High laser power is not practical for thin sheets, because of the limiting factors of machine dynamics and oxygen cutting technology. Typically, an eight-mm thick sheet will require a laser with eight kW power or more. For heavier materials, a 12 kW laser is recommended.

Bed-size

If you want to get the most benefit from your laser cutting machine, you should consider the bed-size. This will determine how much work you can get done. A laser cutting bed is a platform where the metal sheet is placed to be cut. A laser cutting machine with a small bed will be useless for smaller jobs, while a large one will be useless for larger jobs.

Laser cutting bed thickness varies from 8mm to 16mm, although thicker steel plates are used for ultra-high-power fiber laser cutting. The thickness of the bed will affect stability, load-bearing ability, and cutting accuracy. The motor is also a significant factor in the cutting accuracy. Some manufacturers use stepper motors, while others use miscellaneous motors.

After-sales service

After-sales service of a laser-cutting machine is an integral part of the overall quality of this machine. It is important for you to be able to contact the manufacturer of your laser cutting machine and discuss your concerns. Manufacturers usually have professional sales representatives who can answer all of your questions. They will also make sure that you get the service that you need quickly and efficiently.

When selecting a laser cutting machine for your shop, you should pay special attention to the after-sales service. Good after-sales service will ensure that your laser will function smoothly for many years. Longxin Machinery offers free installation and training of its equipment for its users. Their technicians can also assist you with any problems that you may encounter in operating the machine.