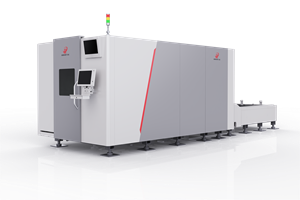

A fiber laser cutting machine price should not be the only deciding factor when purchasing a cutting machine. There are other factors to consider such as the power options, After-sales service, and applications. Keeping these factors in mind when choosing a cutting machine is important to ensure that you make the best purchase possible.

Power options

Fiber laser cutting machines have a wide range of power options. In addition to the standard kW power, higher power options offer additional benefits such as increased cutting range and speed. They also have better edge quality and can cut more material in less time.

Cost of acquisition

A fiber laser cutting machine can save you money on electricity costs. A fiber laser uses less energy and has a lower cost per part than a CO2 laser. Fiber lasers can also cut thinner materials quickly. They also have greater automation features, which increase their productivity and decrease costs. Compared to CO2 lasers, fiber lasers require less space and are ready to use instantly.

After-sales service

A good after-sales service is important for any fiber laser cutting machine. Despite the fact that a fiber laser doesn’t need extensive maintenance, it still needs to be regularly checked and repaired. When it breaks down, it is important that the repair technicians be sent to your site as soon as possible to minimize your downtime.

Applications

The Fiber Laser cutting machine is one of the latest technologies to enter the manufacturing industry. It can be used in a variety of industries, including aerospace, sheet metal, electronic appliances, and automobiles. These machines are designed to produce ultra-precise cuts with extreme efficiency and precision. Their use in various industries is expanding every day, and they are increasingly popular in a variety of applications.

Cost of metal fabrication

The cost of a fiber laser cutting machine for metal fabrication depends on a number of factors, including the type of machine, its model, and the cost of consumables and parts. While most machines run automatically, manual supervision is often needed to ensure quality work. When producing large metal pieces, multiple employees are often required, increasing labor costs. In addition, worker’s compensation is increased with each additional employee. Although this may seem like a good deal, it might not be enough to offset the higher cost of operating the machine. So a autoloading and unloading fiber laser cutting machine should be a good choice.

Cost of CNC laser cutting machine

When purchasing a CNC fiber laser cutting machine, there are several factors to consider. The quality of the pipe, the exchange platform, and the protective cover can all impact the cost of the machine. You should also take into account the operational costs that come with maintaining a laser system. Once these factors are evaluated, you will be able to determine the total cost of the machine.